How does the diamond wire loop work? What is the cutting principle?

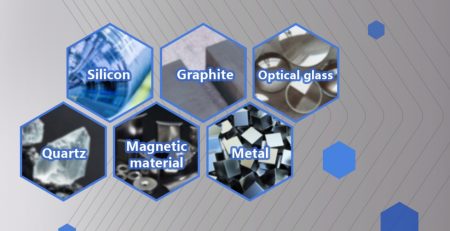

Diamond wire loop cutting (DWLC) uses lines embedded in abrasive diamond crystal particles to cut the material. Because diamond is the hardest, you can ensure that this cutting method will work for any material softer than diamond (almost all materials).

For example, the hardness of common granite is second only to diamond, and natural stones such as marble and quartz are usually known for their hardness, which also makes diamond wire cutting the preferred method of extracting natural stone in quarries around the world.

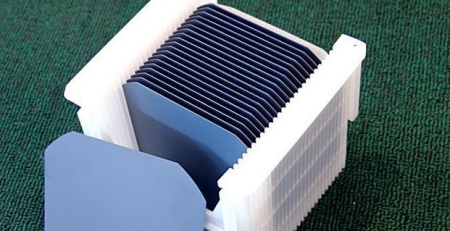

Diamond Wire saws typically use oil and water for lubrication and cooling, and are in principle comparable to reciprocating saws and band saws, except that they use diamond particles instead of serrations to cut the sheet. A wire may consist of one or more strands braided together to form a cable. The abrasive properties of a single strand wire saw can be made by gluing synthetic diamond particles directly to the wire. Line saws are either continuous (also known as circular saws or wire saws) or oscillating (or reciprocating), and the wire itself is also commonly referred to as a “blade”.

Endless Diamond wire loop cutting produces less waste than conventional blades, which can lead to significant cost savings when dealing with expensive materials, and unlike slurry saws that use bare wire and abrasive cutting fluids (which are difficult to handle),Diamond wire loop cutting uses clean water (or oil), and some materials can even be dry cut. Another advantage of loop cutting is speed. Capable of cutting 35 to 40 square feet of granite per hour (on average), four to five times faster than previous technologies, and with minimal human effort after installation.