How about diamond looped wire machining metal alloys?

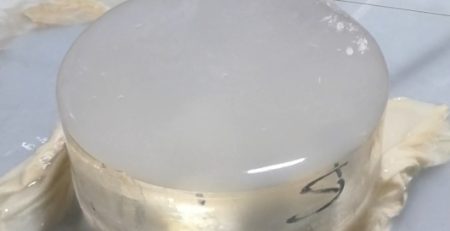

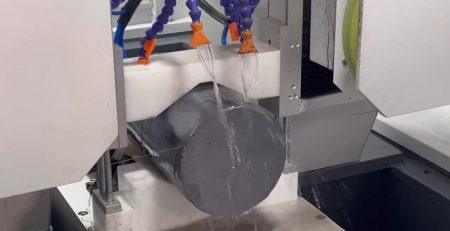

Diamond looped wire cutting technology demonstrates outstanding performance in the processing of metal alloys, bringing significant improvements to the metal manufacturing industry. This efficient cutting method not only accelerates the production process but also provides a higher level of cutting precision and quality.

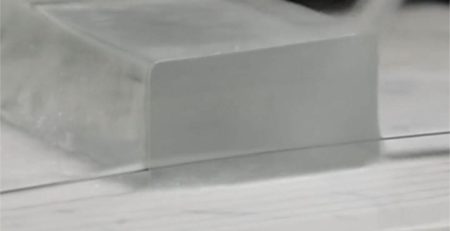

Metal alloys pose challenges for traditional cutting methods due to their complex composition and hardness. However, diamond wire cutting technology successfully addresses these challenges with its exceptional hardness and wear resistance. As a cutting tool, diamond not only swiftly and accurately cuts through metal alloys but also boasts a longer lifespan, effectively reducing production costs.

The efficiency of this technology also enhances flexibility in the metal manufacturing industry. The high speed of diamond looped wire cutting means shorter processing cycles, allowing production to quickly meet market demands. Furthermore, its precision ensures the accuracy of metal alloy components, making it suitable for various industrial sectors, including aerospace, automotive manufacturing, and more.

The efficiency of this technology also enhances flexibility in the metal manufacturing industry. The high speed of diamond looped wire cutting means shorter processing cycles, allowing production to quickly meet market demands. Furthermore, its precision ensures the accuracy of metal alloy components, making it suitable for various industrial sectors, including aerospace, automotive manufacturing, and more.

In summary, diamond looped wire cutting technology excels in the processing of metal alloys, providing an advanced and reliable cutting solution for the metal manufacturing industry. It propels the industry towards more efficient and precise manufacturing processes.