Silicon carbide wafer application and future development trend

Silicon carbide wafer application and future development trend

Silicon carbide (SiC) is the main development direction of the power semiconductor industry, and its use in the manufacture of power devices can significantly improve power utilization. In the foreseeable future, new energy vehicles will be the main application scenarios of silicon carbide power devices.

Compared with traditional silicon materials, silicon carbide is a typical representative of the third generation of semiconductor materials. It has the characteristics of wide bandwidth, high temperature resistance, high pressure resistance, high frequency, high power and radiation resistance.

It has the advantages of fast switching speed and high efficiency, which can greatly reduce product power consumption, improve energy conversion efficiency, and reduce product volume. It will be the most widely used base material for making semiconductor chips in the future.

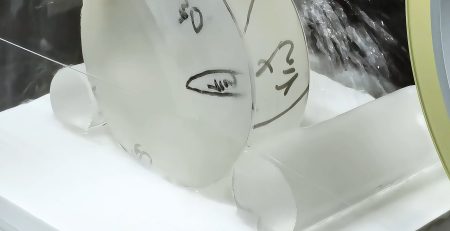

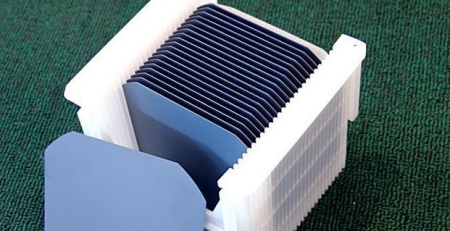

Silicon carbide wafers are single crystal flakes formed by cutting, grinding, polishing and cleaning silicon carbide crystals. As a semiconductor substrate material, silicon carbide wafers can be made into silicon carbide-based power devices and microwave radio frequency devices through epitaxial growth and device manufacturing. It is an important basic material for the development of the third-generation semiconductor industry.

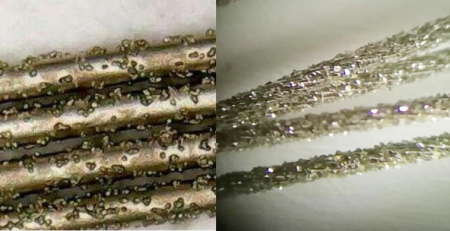

Silicon carbide wafer cut SIC Wafer cut with endless diamond wire loop

According to the different resistivity, silicon carbide wafers can be divided into conductive type and semi-insulating type. Among them, conductive silicon carbide wafers are mainly used to manufacture high temperature and high voltage power devices, and the market scale is large; semi-insulating silicon carbide substrates are mainly used in microwave radio frequency devices and other fields. With the accelerated construction of 5G communication networks, the market demand has increased significantly.

Silicon carbide has a wide range of applications

Due to its wide band gap, it can be used to make ultraviolet detectors or blue light diodes that are almost unaffected by sunlight; Its withstand voltage or electric field is 8 times that of silicon and gallium arsenide, and it is especially suitable for the manufacture of high-voltage and high-power devices such as high-voltage diodes, power triodes, and high-power microwave devices.

And has a high saturation electron migration speed, can be made into various high-frequency devices (radio frequency and microwave);

Silicon carbide is a good conductor of heat, and its thermal conductivity is better than any other semiconductor material, which allows silicon carbide devices to work well at high temperatures.

Silicon carbide (SiC) is an ideal material for high-power devices and the first-generation basic material for the semiconductor industry. Currently, more than 95% of the world’s integrated circuit components are made of silicon. With the development of applications such as electric vehicles and 5G, the demand for high-power, high-voltage, and high-frequency devices is rapidly increasing.

When the voltage is greater than 900V, the shortcomings of silicon-based power MOSFETs and IGBTs will be exposed, which will be limited in many aspects such as conversion efficiency, switching frequency, and operating temperature.

Silicon carbide (SiC) has a large band gap (3 times that of Si), high thermal conductivity (3.3 times that of Si or 10 times that of GaAs), high electron saturation mobility (2.5 times that of Si), high breakdown electric field (5 times that of Si or GaAs), etc.

It is widely used in extreme environments such as high temperature, high pressure, high frequency, high power electronic devices, aerospace, military industry, and nuclear energy.