Simple understanding of alumina ceramics

Simple understanding of alumina ceramics

Alumina ceramics are the most common advanced precision ceramic materials, and are also relatively traditional materials. High purity alumina ceramics have been widely used in many industries as an excellent ceramic material. This material has excellent performance in electrical insulation, high thermal conductivity, high chemical resistance, good wear resistance, and low thermal expansion.

Alumina ceramics can be divided into multiple application levels based on their alumina content, of which 99% are used to make high-temperature crucibles, refractory furnace tubes, and special wear-resistant materials, such as ceramic bearings, ceramic seals, and water valve pieces; 95% – 96% alumina ceramics are mainly used as corrosion resistant and wear-resistant components and circuit boards.

Properties of alumina:

Excellent electrical insulation (1 × 10 14〜1 × 10 15 Ω cm);

Medium to ultra high mechanical strength (300 to 630 MPa);

Extremely high compressive strength (2000 to 4000 MPa);

High hardness (15 to 19 GPA);

Medium thermal conductivity (20 to 30 W/MK);

High corrosion and wear resistance;

Good grinding performance;

Low density (3.75 to 3.95 g/cm3);

The operating temperature without mechanical load is 1000 to 1500 ° C;

Biological inertia, food compatibility.

Overview of the differences between alumina ceramic rods and zirconia ceramic rods

Ceramic rods, also known as ceramic rods, are mainly made of zirconia ceramic and alumina ceramic raw materials and calcined. The market demand for ceramic rods is very large, and they have been widely used in national defense, aerospace, industrial production, and other industries. The need for ceramic rods varies from field to field. The main issues to be considered are: wear resistance, fire resistance, high temperature resistance, corrosion resistance, and wettability of ceramic rods.

The ceramic rods are mostly ivory white, and the commonly used colors are dark blue ceramic rods, light yellow ceramic rods, gray black ceramic rods, etc

Zirconia ceramic rod:

Zirconia ceramic rod has good wear resistance, high hardness, strong compression resistance, and a density of over 6.0. The main advantage of zirconia ceramic rod is its good ductility! Zirconia ceramic rods are widely used in industries such as motor shafts, motor shafts, grinding, needle gauges, and especially in the heat removal commodity industry, rather than traditional stainless steel center rods.

Alumina ceramic rod:

The alumina ceramic rod can withstand high temperatures up to about 1700 degrees Celsius, and has good electrical conductivity, impact toughness, and high temperature resistance. The alumina ceramic rod has low density and convenient transportation, but its ductility is poor and it is easy to crack and crush; Alumina ceramic rods are widely used and have already infiltrated various fields such as electronic and electrical, mechanical equipment manufacturing, and so on

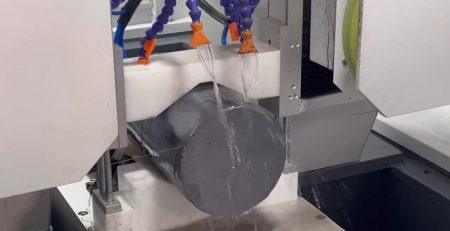

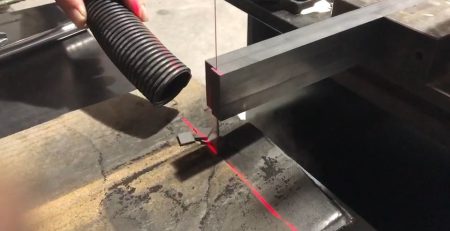

Alumina ceramic-diamond wire loop saw/endless diamond wire-Ensoll #ceramic #alumina