Complete Guide to Diamond Wire Cutting for Lenses

Introduction:

Welcome to our comprehensive guide on diamond wire cutting for lenses. In this article, we will explore the world of lenses, discuss why diamond wire loop cutting is preferred for lens cutting, and provide a step-by-step guide on how to effectively cut lenses using this method. Additionally, we will highlight some important considerations to keep in mind during the process. Whether you are a professional lens cutter or a DIY enthusiast, this guide will equip you with the knowledge and techniques required to achieve precise lens cutting results.

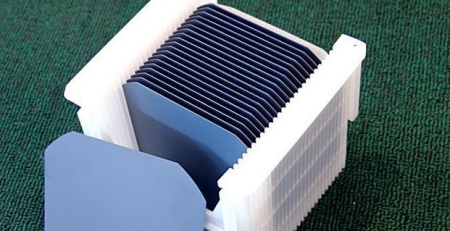

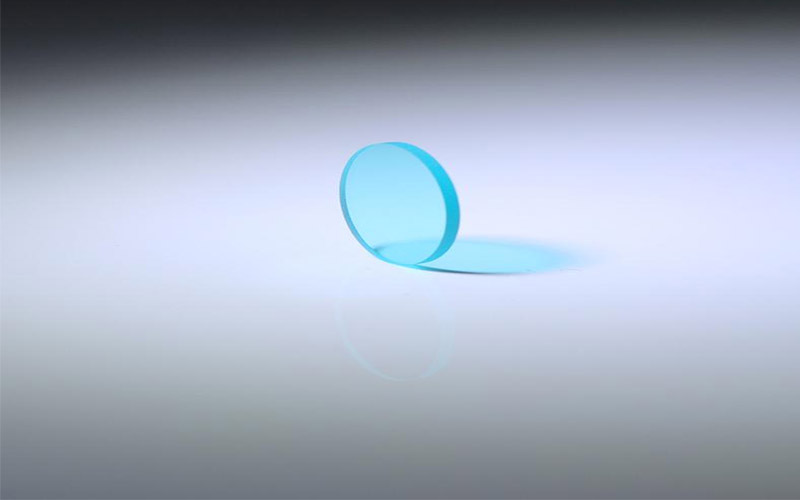

What are Lenses?

Lenses are transparent optical devices with curved surfaces that are used to control the passage and focusing of light. They are commonly found in various optical systems, such as cameras, microscopes, telescopes, and eyeglasses. Lenses can be made from different materials like glass, plastic, or synthetic materials, and they come in various shapes and sizes depending on their specific application.

Why Diamond Wire Cutting for Lenses?

Why Diamond Wire Cutting for Lenses?

- Diamond wire cutting is preferred for lens cutting due to its precision, efficiency, and ability to handle delicate materials. Lenses, especially those made from glass or high-quality optical materials, require precise and clean cuts to maintain their optical properties. Diamond wire, equipped with diamond-coated blades, offer exceptional cutting accuracy and minimize the risk of chipping or damaging the lens surface.

- Unlike traditional cutting methods, diamond wire cutting provides greater control over the cutting process, allowing for intricate designs and complex shapes. The diamond-coated blade’s high-speed rotation combined with water cooling ensures minimal heat generation, reducing the chances of thermal stress on the lens.

Preparation for Diamond Wire Loop Cutting

Preparation for Diamond Wire Loop Cutting

Before beginning the diamond ring saw cutting process, it is essential to prepare adequately.

- Safety First: Prioritize safety by donning the necessary protective gear, such as safety glasses, gloves, and a dust mask.

- Workspace Setup: Set up a clean and well-ventilated workspace. Clear away any clutter and ensure sufficient lighting for better visibility.

- Lens Marking: Mark the lens surface with the desired cutting line using a marker or template. Ensure the marking is precise and aligned with your intended design.

- Equipment Inspection: Thoroughly inspect the diamond ring saw and the blade before use. Check for any damages or signs of wear and tear. Replace the blade if necessary.

- Water Cooling System: Connect and test the water cooling system attached to the diamond ring saw. Adequate water flow is crucial to maintain the blade’s temperature and reduce friction during cutting.

Steps for Diamond Wire Loop Cutting

Now, let’s dive into the step-by-step process of cutting lenses using a diamond wire:

Step 1: Secure the Lens:

Carefully position and secure the lens on the cutting surface, ensuring it remains stable throughout the cutting process. Use clamps or other appropriate methods to hold the lens securely.

Step 2: Start Cutting:

Switch on the diamond ring saw and slowly lower the blade onto the marked cutting line. Avoid applying excessive pressure, as it may lead to chipping or cracking of the lens.

Step 3: Water Cooling:

Continuously monitor the water cooling system during cutting to ensure a constant flow of water over the blade and the lens. This helps to minimize heat buildup and prevents damage to the lens due to excessive heat.

Step 4: Follow the Cutting Line:

Carefully follow the marked cutting line while maintaining a smooth and steady cutting motion. Take your time and make small adjustments, if necessary, to achieve the desired cut.

Step 5: Clean and Inspect:

Once the cutting is complete, remove the lens from the cutting surface and clean it thoroughly to remove any debris or residue. Inspect the cut edges for smoothness and precision. If needed, use fine-grit sandpaper or polishing tools to refine the edges.

Important Considerations:

Safety Measures: Always prioritize safety by wearing appropriate protective gear and working in a well-ventilated area. Follow the manufacturer’s instructions for safe operation of the diamond ring saw.

Water Cooling: Ensure an adequate water cooling system is in place to prevent overheating of the blade and lens. Monitor the water flow throughout the cutting process and adjust as needed.

Cleanliness: Keep the lens and cutting area cleanto avoid any contamination or damage to the lens. Regularly clean the lens and the cutting surface to remove debris and maintain optimal cutting conditions.

Conclusion:

Diamond wire loop cutting is an effective and precise method for cutting lenses, offering control, accuracy, and minimal damage to the lens surface. By following the steps outlined in this guide and considering the important factors, you can achieve excellent results in lens cutting. Remember to prioritize safety, choose the right equipment, and maintain proper water cooling during the process. With practice and attention to detail, you can create beautifully cut lenses for various optical applications. Happy cutting!