Simple understanding of industrial sapphire

Simple understanding of industrial sapphire

In the gem world, all kinds of gem grade corundum other than ruby are called sapphires. The main component of sapphire is aluminum oxide (Al ∈ O;). Because it contains trace elements such as iron and titanium, it appears blue, sky blue, light blue and other colors.

Industrial sapphires generally refer to gemstones that cannot reach the level of decoration, take industrial diamonds as an example. The gear shafts in good mechanical watches are all made of diamonds,

However, this kind of diamond can only be used for tools, not for decoration. For example, glass knife, the diamond of the blade is also diamond. The truth is the same. Whether it is man-made or natural, and its level cannot reach the level of decoration, it is used for industrial purposes.

Industrial grade sapphire is mainly used for two purposes:

One is substrate materials, such as LED semiconductor substrate materials.The other is window materials, such as dial, aerospace, precision manufacturing, etc.

The large-sized flat sapphire used in the aerospace field, the large-sized high-quality sapphire, graphene, night vision infrared transmission equipment, satellite space technology and mobile phone screen in the semiconductor field, photoelectric field and military industry field also belong to. This is also due to the high temperature resistance, corrosion resistance, high strength, high hardness, good wear resistance, high insulation, good air tightness, good thermal insulation and other characteristics of corundum gemstones. This kind of gemstone is cheap for tens of dollars a piece. The better the quality, the higher the price. Similarly, the more high-tech fields need higher quality sapphires.

Processing technology of sapphire:

Seed crystal – long crystal – orientation – pulling out rod – rolling grinding – quality inspection to obtain mature crystal rod, as shown in the figure

Crystal

Crystal bar

After the crystal bar, the wafer is obtained through orientation, slicing, grinding, chamfering, polishing, cleaning and tasting. As shown below:

Wafer

The most important link in these processes is the crystal cutting into crystal bars and the cutting link of crystal bars into wafers. This link will affect the number of consumables, cutting quality, subsequent grinding thickness, etc.

At present, the mainstream of the market is the diamond long wire cutting machine, which can be divided into one-way cutting and two-way cutting, but the equipment is huge and expensive. Laser cutting has been gradually replaced.

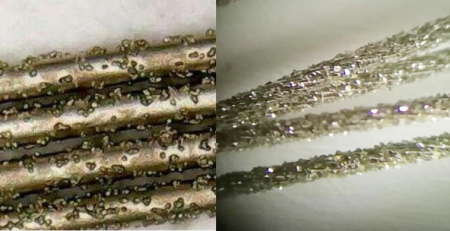

In the past three years, diamond wire loop cutting machine has appeared again. Compared with long wire, laser, band saw and water jet cutter, it has improved a lot in terms of productivity, consumables and accuracy. As shown in the figure: