Prospects of Diamond Looped Wire Saw Cutting in Processing Optical Glass

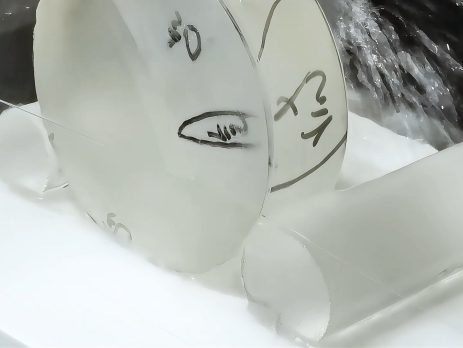

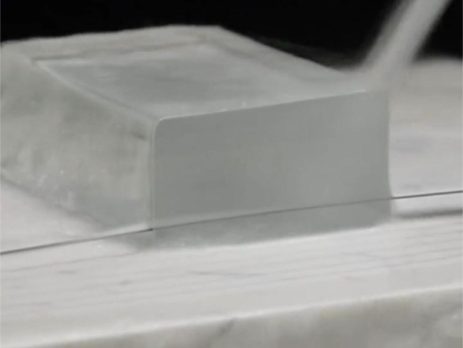

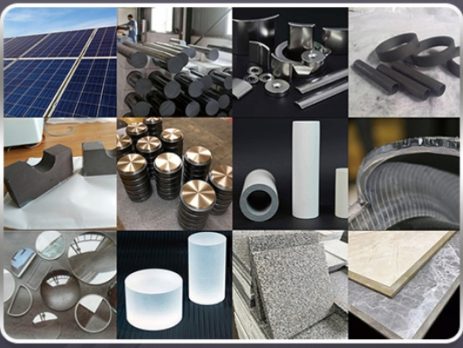

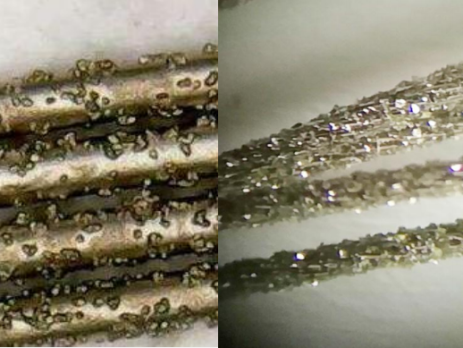

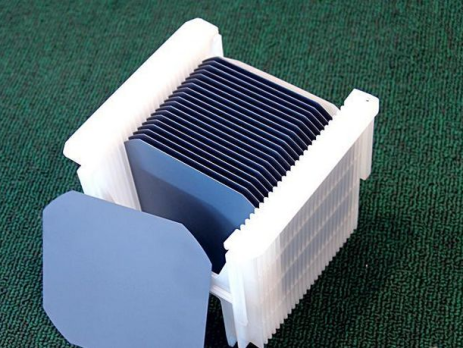

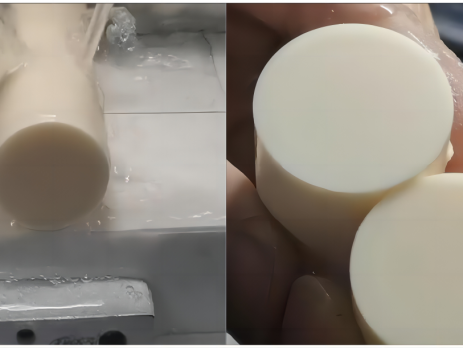

Diamond looped wire cutting has vast prospects in the processing of optical glass, and its unique advantages make it a crucial tool in the field of optical glass manufacturing. Here are the prospects of diamond wire cutting in processing optical glass:High Precision and Fine Cutting: Diamond wire saw cutting, with its highly precise cutting capabilities and fine operation, is suitable for the precise processing of optical glass. This is essential for manufacturing high-precision optical components, including lenses, prisms, and...