Silicon carbide cutting preferred equipment – diamond wire loop cutting saw

There are many kinds of cutting methods of silicon carbide, among which common ones include grinding wheel cutting, diamond wire saw cutting, laser cutting and so on.

Grinding wheel cutting is the use of high-speed rotating grinding wheel to cut and remove silicon carbide, which is suitable for various shapes and sizes of silicon carbide cutting workpiece, but it is not suitable for specific special shapes of silicon carbide cutting.

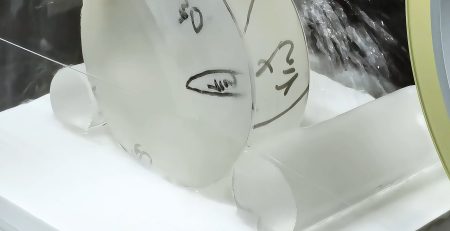

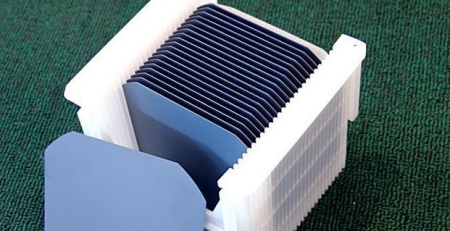

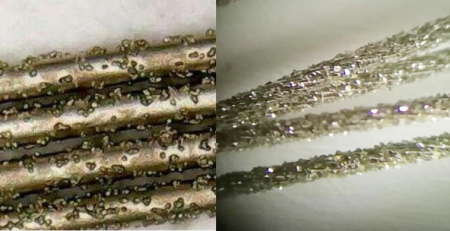

Diamond wire saw cutting is a way of using a wire saw to cut materials with high-speed rotation, which has the advantages of high precision and high efficiency, and is suitable for cutting a variety of hard and brittle materials.

Laser cutting is the use of high-energy laser beam irradiation on the surface of silicon carbide, so that the surface material quickly melt, vaporize or reach the ignition point, while the high-speed airflow will melt or burn the material away, so as to achieve cutting. Laser cutting has the characteristics of high precision, high speed and high adaptability, but requires the use of expensive equipment and high energy consumption.

Laser cutting is the use of high-energy laser beam irradiation on the surface of silicon carbide, so that the surface material quickly melt, vaporize or reach the ignition point, while the high-speed airflow will melt or burn the material away, so as to achieve cutting. Laser cutting has the characteristics of high precision, high speed and high adaptability, but requires the use of expensive equipment and high energy consumption.

In summary, the choice of cutting method depends on the specific material properties, size and processing needs.With the continuous development of technology, more and more enterprises are more inclined to use diamond wire loop saw cutting, under the premise of maintaining high precision and efficiency, the cost is also the lowest!