What are the characteristics of diamond looped cutting wire

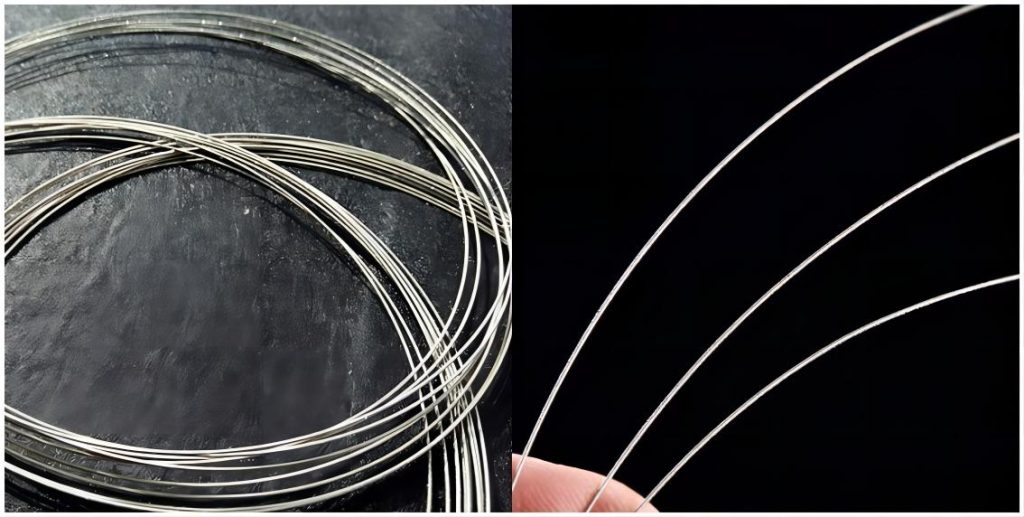

The diamond looped wire saw has characteristics such as high efficiency, high precision, wide range of applications, material conservation, uniform diamond distribution, no chipping,and environmental friendliness. These characteristics make the diamond looped wire saw widely used in various fields.

Specific features are as follows:

High efficiency-The diamond looped wire saw adopts a unique ring design, providing higher tool life and more stable cutting performance. With a linear speed of up to 40-60 m/s, it has high cutting efficiency, significantly improving production efficiency.

High precision-The diamond looped wire saw uses high-quality diamonds, combined with precise production processes and control systems, to provide precise cutting accuracy.

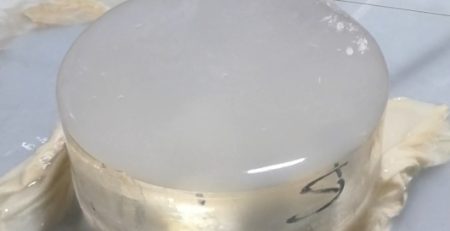

Wide range of applications-Diamond looped wire saw is widely used in construction, industrial manufacturing, jewelry manufacturing, and scientific research due to its high efficiency and precision. In the construction field, it is used for cutting materials such as concrete, marble, and granite. In industrial manufacturing, it is used for cutting metal materials, glass, etc. In jewelry manufacturing, it can achieve high-precision cutting of various complex gemstones. In scientific research, its stability and high precision also make it widely used.

Material conservation-The design of the diamond wire saw allows for a small cutting gap and reduced material loss, which is particularly important for valuable materials.

Uniform diamond distribution: The diamond wire saw has a uniform distribution of diamonds, making the cutting process more stable and improving cutting quality.

No chipping: The diamond looped wire saw does not produce chipping during the cutting process, improving cutting quality.

Environmental friendliness: The diamond looped wire saw generates less dust and noise during the cutting process, reducing environmental pollution.