What materials can diamond wire loop cut?

What diamond wire loop?

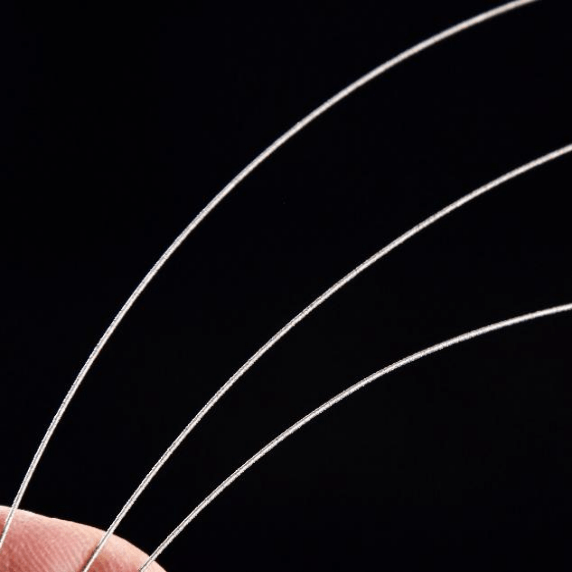

Diamond wire loop refers to a cutting tool that consists of a loop-shaped wire embedded with diamond particles. This tool is commonly used in various industries for cutting and shaping different materials.

Principle of diamond wire loop cuttin:

The principle of diamond wire loop cutting is based on the hardness and abrasiveness of diamond particles. Diamond is the hardest known material, and its sharp edges and points make it an excellent cutting agent. The diamond particles embedded in the wire loop create a cutting edge that is capable of slicing through various materials with precision and efficiency.

The diamond wire loop is typically attached to a cutting machine or a handheld tool. The loop is tensioned and guided to maintain its shape and stability, and it is continuously fed with a coolant, such as water or oil, to maintain its cutting efficiency and prevent overheating. The loop is then brought into contact with the material to be cut, and the cutting process is initiated. The movement of the loop, combined with the constant supply of coolant, allows for a smooth and controlled cutting action.

The diamond wire loop is typically attached to a cutting machine or a handheld tool. The loop is tensioned and guided to maintain its shape and stability, and it is continuously fed with a coolant, such as water or oil, to maintain its cutting efficiency and prevent overheating. The loop is then brought into contact with the material to be cut, and the cutting process is initiated. The movement of the loop, combined with the constant supply of coolant, allows for a smooth and controlled cutting action.

What materials can be cut by diamond loop wire?

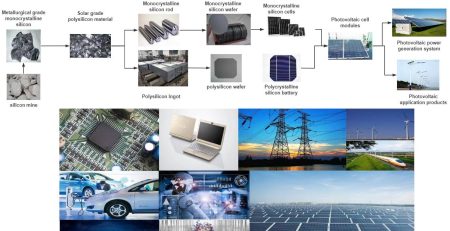

![]() Diamond wire loop cutting is suitable for a wide range of materials, including but not limited to:

Diamond wire loop cutting is suitable for a wide range of materials, including but not limited to:

- Stone: Diamond wire loop cutting is commonly used in the stone industry for cutting and shaping stones such as marble, granite, limestone, and sandstone. It is often used in the fabrication of countertops, tiles, and decorative pieces.

- Concrete: Diamond wire loop cutting is effective in cutting and removing concrete in construction and demolition projects. It is used for tasks such as cutting through concrete walls, slabs, and beams.

- Metal: Diamond wire loop cutting can be used to cut various metals, including steel, aluminum, and copper. It is commonly used in metal fabrication and manufacturing processes.

- Glass: Diamond wire loop cutting is utilized in the glass industry for cutting and shaping glass materials. It is used in the production of glass panels, windows, and glassware.

- Composites: Diamond wire loop cutting can be employed to cut through composite materials, which are made by combining different materials such as carbon fibers and resins. It is often used in industries such as aerospace and automotive for cutting composite components.

- Ceramics: Diamond wire loop cutting is effective in cutting ceramic materials such as tiles, porcelain, and ceramic components. It is commonly used in the production of ceramics for construction and decorative purposes.

- Semiconductor materials: Diamond wire loop cutting is utilized in the semiconductor industry for dicing and shaping semiconductor materials, such as silicon wafers. It is crucial in the manufacturing of electronic devices and components.

- Other materials: Diamond wire loop cutting can also be used to cut materials such as plastics, rubber, and composites. It is employed in various industries for cutting and shaping different types of materials.

In summary

Diamond wire loop cutting is a versatile and efficient method for cutting and shaping various materials. From stones and concrete to metals and glass, diamond wire loop cutting finds application in numerous industries. Its ability to provide precise and controlled cuts makes it a valuable tool in manufacturing, construction, and other sectors.